ABCT Product Suite

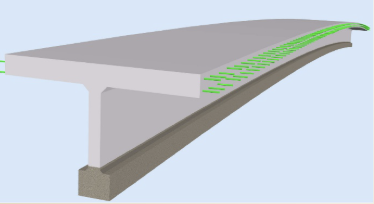

Refined prestressed concrete Elements (Ultra-T™)

Innovative in the fabrication process and design methodology for producing refined prestressed concrete elements by pre-compressing the bottom flange made of ultra high performance contrete, and later fabricating the rest of the beam using high performance concrete.

Benefits

The Ultra-T™ system offers a range of structural and economic advantages that make it ideal for modern bridge construction. Its increased durability and low life cycle cost provide long-term value, while its design supports accelerated construction timelines, especially in field applications. The system offers better control of differential camber and eliminates the need for anchorage zone reinforcement, debonding, and draping—streamlining the fabrication process. With no tension in the deck due to prestress, including in multi-span applications, Ultra-T™ is particularly well-suited for link slab connected bridges. Additionally, it enables a significant reduction in superstructure depth and shipping weight, while maintaining a total superstructure weight comparable to steel girder systems. Hybrid Tees used in Ultra-T™ are lighter than conventional Deck Bulb Tees cast with HP concrete, and the system is compatible with lightweight concrete and a variety of reinforcement types, further enhancing design flexibility and construction efficiency.Patent

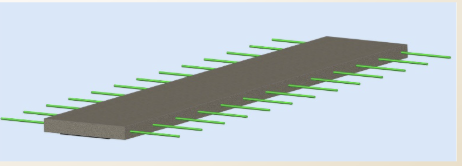

Prefabricated Link Slabs (Ultra-LS™)

Method of designing, manufacturing, and installing PLS-UHPC as connections between bridge spans

benefits

The Ultra-LS™ system is engineered to optimize long-span precast bridge construction through enhanced performance, cost-efficiency, and design flexibility. Its extended span capacity reduces the number of supports required, minimizing foundation work and simplifying substructure design. Ultra-LS™ offers improved load distribution and increased stiffness, contributing to long-term durability and reduced maintenance needs. The system eliminates the need for post-tensioning and complex reinforcement detailing, accelerating the production process and reducing fabrication costs. It also achieves a low profile with a shallow superstructure depth, making it ideal for constrained vertical clearance conditions. By enabling longer spans without sacrificing strength or stability, Ultra-LS™ provides an efficient alternative to steel or cast-in-place solutions—supporting faster installation, lower overall life cycle costs, and superior performance in both urban and rural bridge applications.