Case Studies & Resources

FHWA Resources

Federal Highway adriminstration

“the fact that increasing the tensile resistance of concrete will allow it to better engage the connectors originating from a prefabricated concrete element”

- Dr Ben Graybeal FHWA

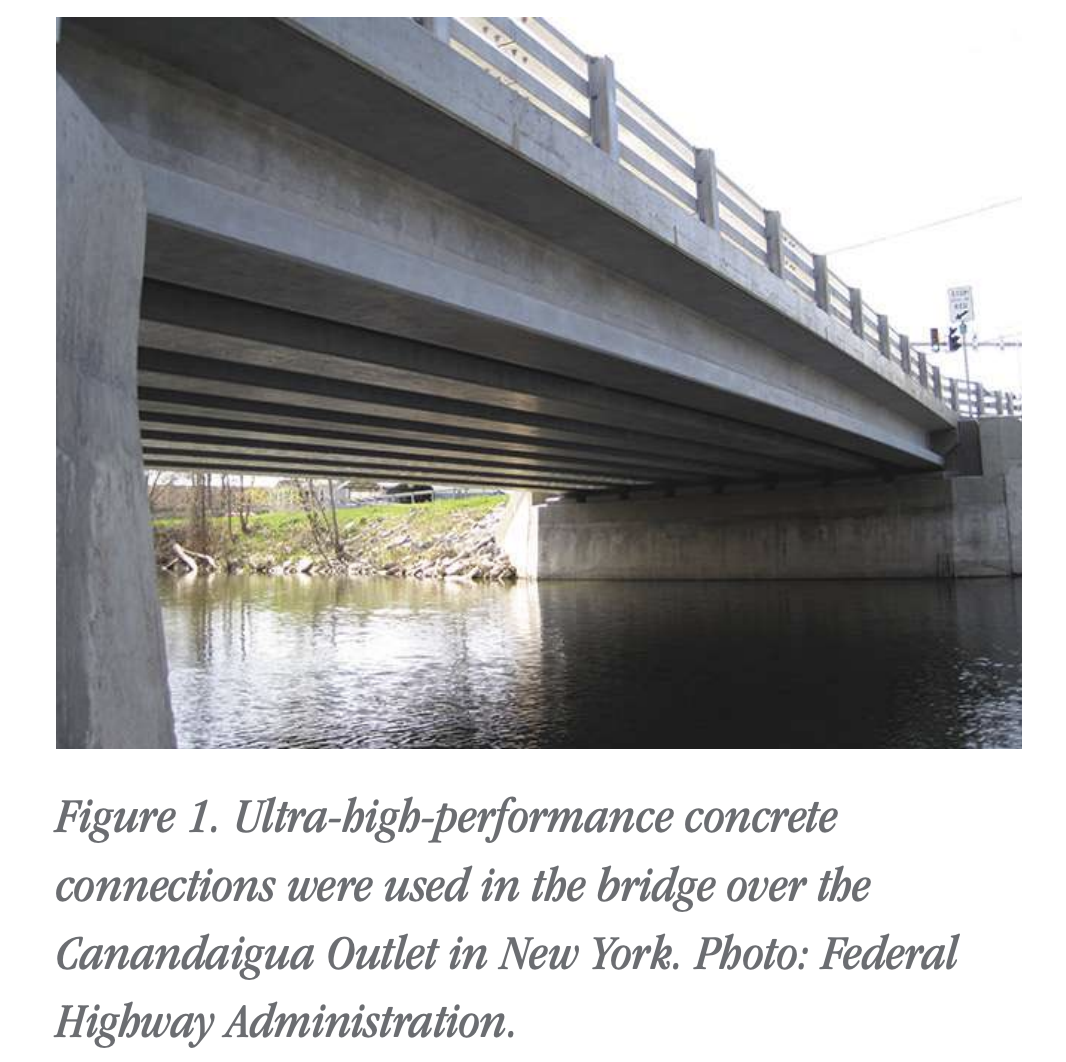

Pairing Prefabricated Bridge Elements with UHPC Connections

This FHWA study highlights how pairing prefabricated bridge elements with ultra-high-performance concrete (UHPC) connections improves constructability, durability, and long-term performance. Traditional field-cast joints are prone to durability issues, but UHPC enables simpler details and significantly extends service life, making it a key enabler for accelerated bridge construction.

This FHWA report (2013) consolidates global research and U.S. deployment of Ultra-High-Performance Concrete (UHPC) for highway and bridge infrastructure. Compiled from hundreds of studies, it documents UHPC’s superior strength, durability, and emerging applications, serving as both a technical foundation and roadmap for agencies—including DOTs and design professionals—to adopt UHPC in accelerated bridge solutions.

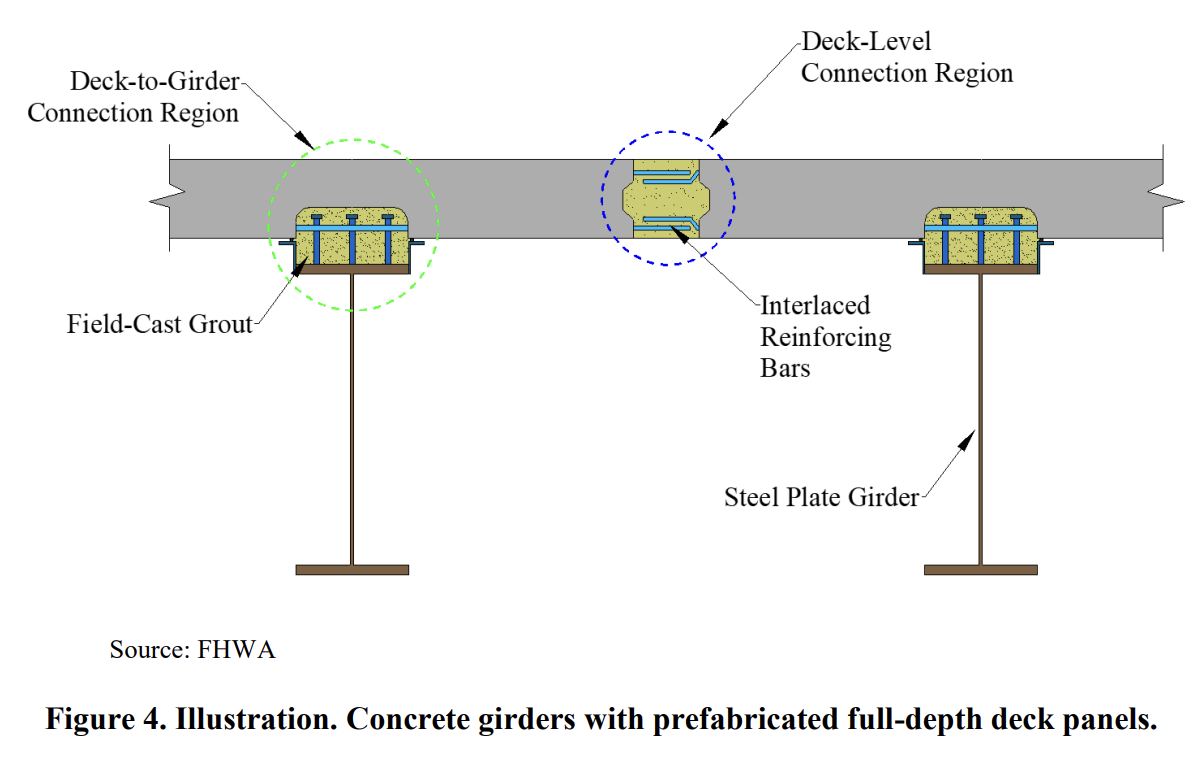

Performance of Grouted Connections for Prefabricated Bridge Deck Elements

This FHWA study investigates how different field-cast grout materials perform in connecting adjacent prefabricated bridge deck panels—a key concern for Accelerated Bridge Construction. Through extensive laboratory testing of full-scale deck-level connections under cyclic, fatigue, and ultimate loads, the research highlights that connection performance is strongly influenced by grout type (cementitious, epoxy, magnesium phosphate, UHPC), precast surface preparation, and reinforcement detailing. Notably, UHPC and carefully prepared surfaces (e.g., exposed aggregate) deliver significantly enhanced bond strength and

durability, positioning them as superior solutions for robust,

long-lasting bridge deck connections.